Oilless rotary vane vacuum pump carbon vanes pump

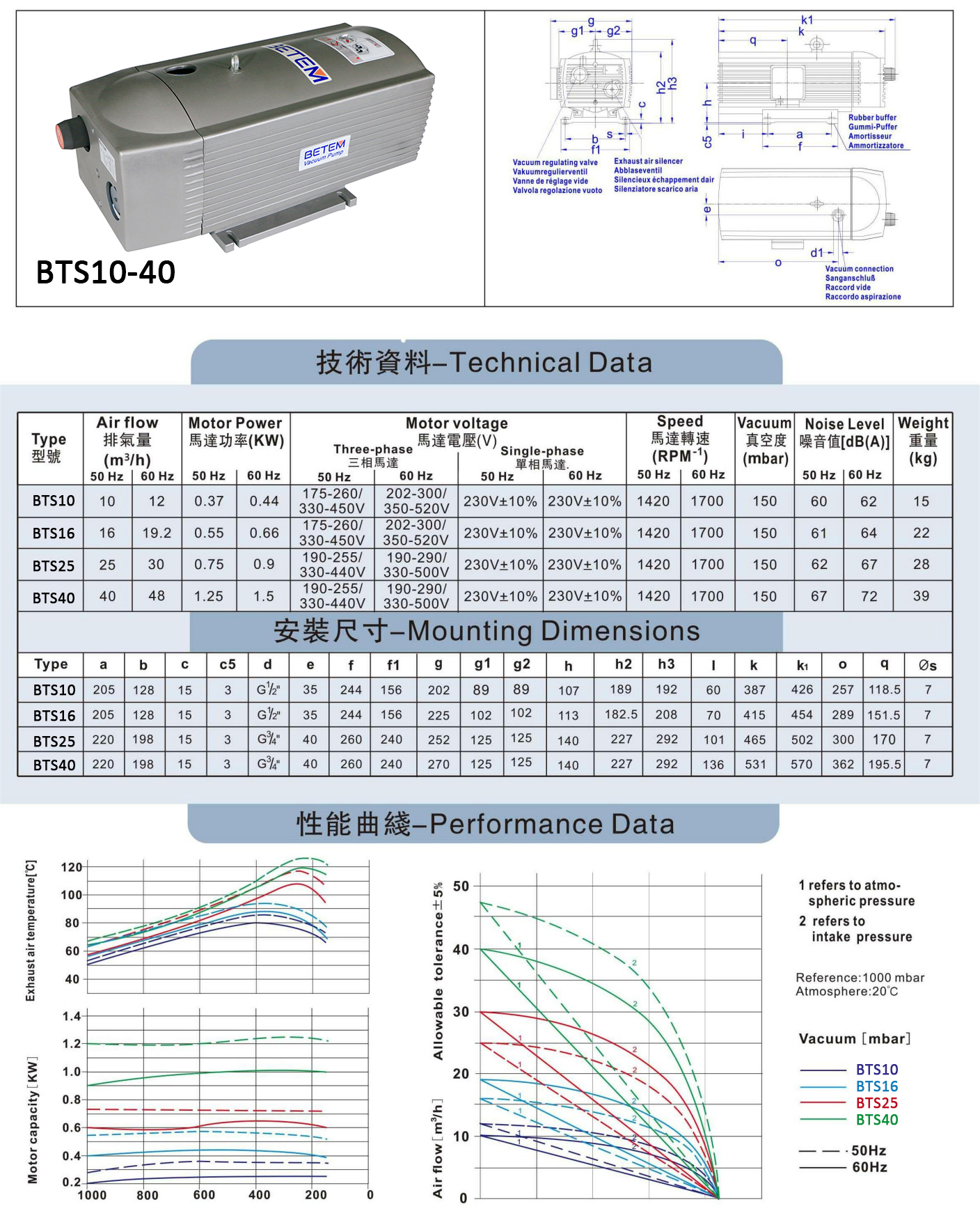

Item No.: BTS-16

Description

The benefits of the new range are visible at a glance: maintenance and control panel are placed on one side only for easy access to filters and valves. Additional features include heat reduction through large cooling air pathways and vents. Design features such as the solid ribs, optimized cooling air circulation, thermal separation of suction and compression chambers within the filter housing, as well as a minimum number of connected heat transferring parts reduce machine temperatures.

An oil-free vacuum pump, also referred to an oil-less vacuum pump or dry running vacuum pump, is essentially a pump that does not use lubricants in the chamber to create a vacuum or cool the pump. In oil-lubricated machines lubrication is used a seal the vacuum chamber and cool the pump. Oil-free machines use other means to cool the machine during operation such as water or air cooling.

Features:

Features of Rotary Vane Vacuum Pump:

a. Almost completely maintenance-free

b. Have a wide range of performance

c. Robust yet lightweight

d. Reliability - Built to last

e. 50/60 Hz Voltage range motors

f. Low level of noise

g. Easy installation

h. No vibration, complete dynamic stability

Applications:

Analytics (mass spectrometry, electron microscopy)

Coating technology (surface protection, decorative films, display units, monitor screens)

Vacuum metallurgy (vacuum soldering, vacuum sintering, vacuum alloys, and furnace construction)

Leak detection technology (vacuum systems, automotive tanks, airbag cartridges, packaging)

Lighting industry (light bulb manufacture)

Drying industry (vacuum drying, transformer drying)

Contact: Jack Huang

Phone: 0086-180-2895-8875

Tel: 0086-769-82223051

Email: info@betempump.com

Add: Houye industrial Park, No.325 Shida Road, Shibu District, LiaoBu Town, Dongguan, Guangdong, China, 523400